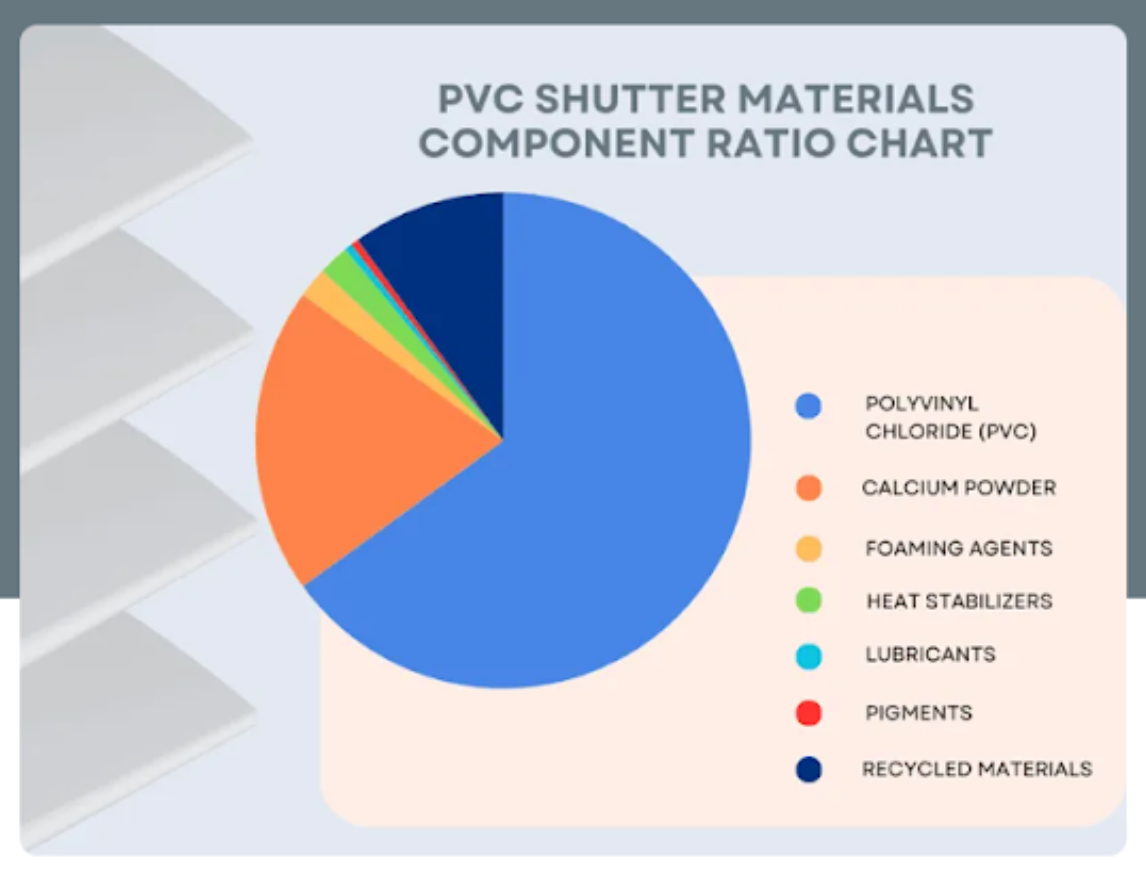

The Materials Components of “The British Made Shutter”

Polyvinyl Chloride (PVC)

The backbone of our plantation shutter materials, PVC, offers strength and durability. Known for its rigidity and resistance to moisture and decay, it ensures longevity and consistent performance.

Calcium Powder (Fillers)

In the formulation of our PVC shutters materials, we introduce calcium powder to augment stability and strength while ensuring cost-effectiveness. This filler enhances rigidity without compromising the shutter’s overall quality. The proportion of calcium powder directly influences the density and weight of the shutter profiles.

Processing Aids

Foaming Agents: These create a lightweight, cellular structure, contributing to better insulation.

Heat Stabilizers: Essential during manufacturing, they prevent degradation and discoloration under heat.

Lubricants: They aid in the smooth processing of PVC, leading to finer finishes.

Pigments:

These ensure the shutters retain their colour and offer UV resistance, preventing fading over time.

Recycled Materials

In our manufacturing process, we ensure that the addition of recycled PVC does not exceed 15%. The use of recycled materials in our shutter parts production aligns with our commitment to sustainability, while also upholding the high-quality standards British Made Shutters is known for.

Processing of PVC Shutters Materials

The manufacturing of PVC shutters materials involves precision and care. We combine these components at specific ratios, ensuring a perfect blend that meets our high standards. The materials undergo heating, moulding, and cooling processes, resulting in shutters that are robust and aesthetically pleasing.

Are PVC Shutters Toxic?

PVC shutters are non-toxic as they are crafted from materials, including Polyvinyl Chloride (PVC) and calcium powder, without the inclusion of harmful substances like aldehydes, benzene, or toxic heavy metals.

PVC stands as a thoroughly secure material for interior window treatments, adhering to stringent safety standards. Given their non-toxic nature, PVC shutters are suitable for all environments, including homes, hospitals, and schools. They do not pose a health risk to adults, children, or pets.

1.

Safe Material Composition

Primary Ingredients: The main materials used in PVC shutters are Polyvinyl Chloride (PVC) and calcium powder.

Additives: Our shutters do not contain aldehydes, benzene, or toxic heavy metals such as lead, chromium, or mercury in their additives. This ensures that the composition is free from harmful substances.

2.

Low VOC Emissions

Formaldehyde and Benzene-Free: The materials used in PVC shutters do not release toxic gases such as formaldehyde or benzene. See Why PVC Shutters are Formaldehyde Free? The materials used in our PVC shutters have undergone rigorous testing, receiving SGS certification for VOC (Volatile Organic Compound) emissions.

3.

Durability and Lack of Maintenance

Their durability means that PVC shutters do not break down or degrade easily, reducing the risk of releasing any harmful particles over time. Additionally, they do not require treatments or finishes that might involve toxic materials.